Digital laser cutting in the corrugated application field is finally a reality

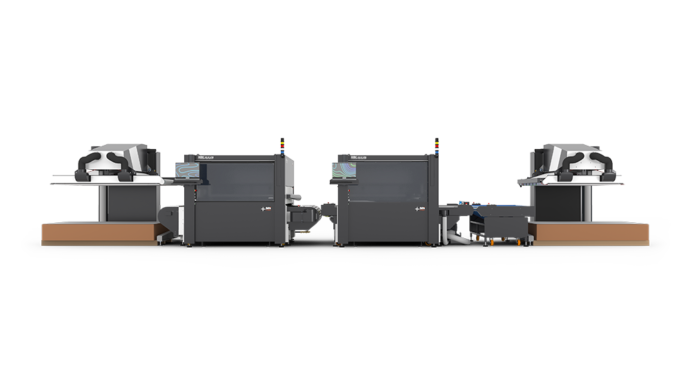

X-Wave Converting

X-Wave Converting is a modular production line, consisting of the following process stations: loading, visioning, digital creasing, laser cutting and unloading, each equipped with specific conveyors.

The entire machining process is “on-the-fly”, without any interruption or pause, thanks to the sophisticated automation of SEI Laser, which keeps the conveyors synchronized.

The transport speed of the material is optimized according to the maximum speeds of each single process, the workflow is therefore carried out without any discontinuity.

A high-resolution vision scanner system equipped with innovative optical sensors allows the registry creasing and laser cutting, compliancy with printing.

Unique Plus:

X-Wave Converting offers numerous unique advantages in corrugated production processes in just one system.

- PRODUCTIVITY

Carbon fiber beams, together with creasing and registry die-cutting, ensure a series production without reservations in terms of quality, precision and accuracy. The productive benefit is up to 6 times greater than the use of traditional blade finishing systems and results in 150 displays/h and 500 boxes/h. - SPEED

The speed and acceleration performances reach values of 4 m/s and 6g. - DIGITIZATION

The complete digitalization of the process makes the change of work extremely fast and intuitive, leading the operator in all phases. - OPTICAL REGISTERS

X-Wave Converting optical registers ensure fast and easy material loading. - SCANNER TECHNOLOGY

The innovative scanner technology for cutting and creasing corrugated board requires no maintenance or calibration over time. - MODULARITY

The system has been specially designed to be modular and integrated into existing workflows.

contacts

Do you need more information about this product?Write to us and we will contact you as soon as possible