LABELEXPO FAIR – SEI Laser, world leader in laser technology, exhibits the latest enhanced version of Labelmaster at the next Labelexpo, in two models with web widths of 350 and 600 mm. With full digitalization, from order receipt to shipment, converters reach a new level of speed and productivity.

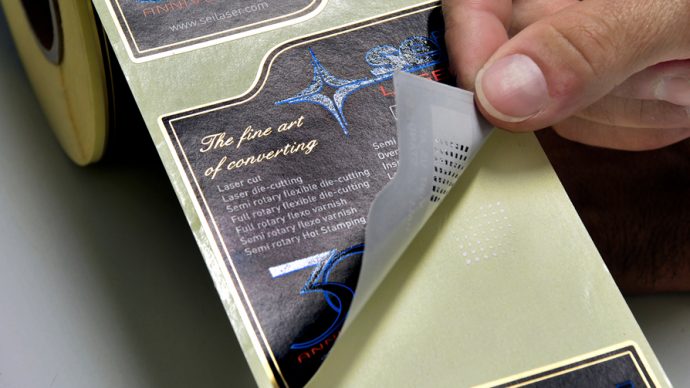

Labelmaster, the most complete and professional modular system for “roll to roll” and “roll to sheet” digital die cutting and finishing, is the perfect solution for the production of self-adhesive labels in all sectors: industrial, wine, food&beverage, beauty, textiles, flexible packaging, promotional, converting and many others. During Labelexpo Europe, visitors will have the opportunity to see the laser processing of different types of labels and special finishings on different materials – such as paper, PP and textile – to appreciate laser versatility and its excellent quality, the result of the work of the engineers from Curno (BG).

«Labelexpo 2019 edition is configured as the definitive consecration of the digital business model, now indispensable in all (or almost all) labeling and packaging segments» says Ettore Colico, Converting Director at SEI Laser. «It is no longer a matter of the well-known special effects but of confidence and respect for a digital technology that has now reached full maturity. Jumbo rolls, automatic motorized knives and “wide web” will be the key points of the SEI Laser stand in Brussels».

More efficiency: Labelmaster is specifically developed to meet the demands of converters and label producers looking for great performance: in an increasingly competitive market, the QR-code/barcode reading system allows you to change work on the fly, ensuring high productivity and completely eliminating setup times. Lastly, the control software, compatible with the most common digital workflows, maximizes efficiency in the various types of work: web to labeling, web to stickers, web to packaging.

Over 100 m/min: SEI Laser will present two configurations of the “Best in Class” laser solution for labels at Labelexpo 2019: Labelmaster in 350 and 600 mm web configurations. Labelmaster, now in its third version, will be equipped with 4 laser heads to reach a constant speed of over 100 m/min, equalling and exceeding the productivity of traditional die-cutting and finishing systems. The speed is kept constant by the “traction control system”, which works in synergy with the control unit of the longitudinal deviation of the material, guaranteeing perfect registration and a high-quality laser processing.

Labelmaster is a modular system, customizable upon purchase or later, with different finishing options: die-cutting, cutting, microperforation, easy-open, engraving, coding and, thanks to optional, different finishes: semy rotary flexo printing/ varnishing, semy rotary hot stamping, inspection, control and slittering.