Labels are everywhere

The labels Vila produces often appear in the food market on fish, cheese, bread, drink, and perfume products. “The rise of online shopping is a key factor. It is something the retail market has to deal with increasingly, resulting in fewer labels finding their way into retail.” Ton explains. “There is so much more out there. Just look at how many labels are used in hospitals. Or labels for machine equipment parts. The label is of vital importance in many logistic processes nowadays. Labels are everywhere.” Ton concludes.

The environment

The environment is a recurring theme in label production. “I see a significant shift towards thinner and recyclable labels. We increasingly produce compostable labels made from the leaves of sugar beets. We always have the environment in mind. We must right now. That’s why our Group upholds the general theme of Optimum Green.” The company also installed solar panels on the roof and took quite a few energy-saving measures.

Premium quality

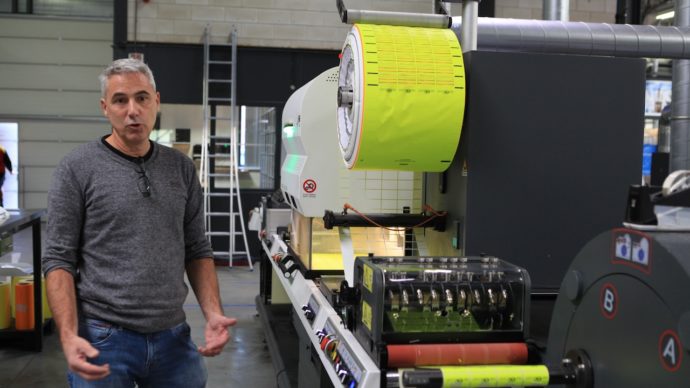

Vila only opts for the best quality machines. That’s why the company selected the HP Indigo label print solution. And when it came to laser cutting, they decided only the Italian producer SEI Laser would do. In Benelux, SEI is represented by Tripa Converting Solutions. “We make small batches in Breda that are produced digitally. The increase in low runs increased our production capacity. We just needed a second SEI LabelMaster to laser cut the labels. It also comes with an extra unit that allows traditional cutting, making it a truly universal solution.” Ton explains.

Creative applications

Laser die-cutting is more than a method allowing Vila to produce short runs efficiently. It also facilitates new and creative label applications. Clients increasingly apply special effects that were not possible before. The second machine expands these options. Ton Reichardt incessantly researches production processes that solidify his market position. “We do our research at trade shows like Labelexpo to get confirmation that we made the right choice. And we found the right partnership with Tripa Converting Solutions and SEI Laser. They make sure that the machine has nearly no downtime, and the service is excellent. This is the best machine out there right now. It runs all the time. This is about more than just the purchase price; it’s about its added value for my production process.”

Fun

Ton is a born and bred entrepreneur. And although Vila is part of a group, the company still feels like his own. And he also runs it with a lot of enthusiasm and a healthy dose of self-criticism. “It still sparks joy.” He states. “The people who work here have been with us for years, and I feel very responsible for them. We do what we’re good at, and I’d like to continue that way for many years to come.” He shares the company results on a big screen, and the numbers are impressible. The factory pushes out over two million labels per day. The machines cover over thirty kilometers of label run lengths each day. Last year alone, the company produced ten million meter run lengths in total. That’s about 650 soccer fields of self-adhesive labels. “A nice market to be active in,” Ton summarizes.

A video story is available at this link (click here)

Thanks to Tripa Converting Solutions